- CNC COMMUNICATION SOFTWARE SERIAL

- CNC COMMUNICATION SOFTWARE SOFTWARE

- CNC COMMUNICATION SOFTWARE DOWNLOAD

- CNC COMMUNICATION SOFTWARE FREE

In either case, encoders are a common input to a PLC, making it another fairly easy hardware integration. They might either be a rotary encoder on the axis motor, or linear strip encoders along the length of the axis. Some CNC machines will also include encoders for location feedback during the machining operation. Since these are digital signals, they are an ideal input device for a PLC.

These digital signals not only provide a sense of location to prevent damaging over-travel of an axis, but they are also used to ‘home’ a machine at the start of a program to provide a sense of location in reference to the workpiece. Input signals are one case where the purpose of the PLC may actually lend itself quite well to signals produced by a CNC machine.Īt a minimum, the CNC frame usually includes some sort of micro limit switch or contactless limit switch.

CNC COMMUNICATION SOFTWARE SOFTWARE

In contrast to the software differences, which were quite extreme, the input and output hardware connections are actually quite similar between the two kinds of controllers. The purpose is not to assert that it is impossible to convert between controllers, but rather to explain the various elements that must be addressed in order for the machine to operate properly.

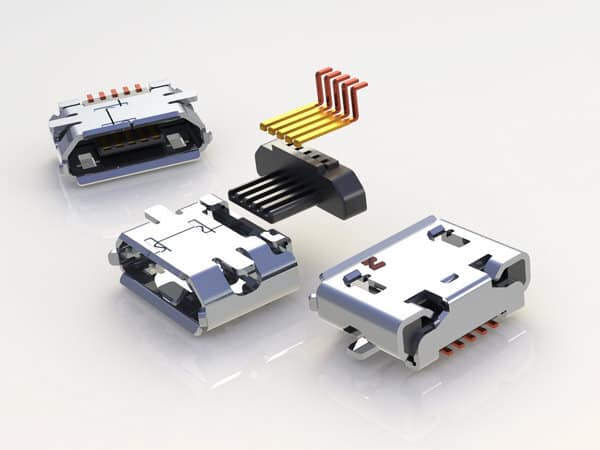

This article discusses a variety of hardware differences between CNCs and PLCs. The software differences are the first challenge. However, there are usually some extra challenges that might make such a substitution very difficult. In some cases, it is possible to use a PLC to drive a CNC machine, since at the very fundamental level they both use digital controllers to drive output devices. In previous articles, we have discussed the differences between the programs and codes that operate control system processes versus the codes that run CNC machines to create parts using machining processes. CNC machining requires specific hardware to accurately perform its job. It can be possible to interchange them, but challenges exist because of the hardware and devices being controlled.įigure 1. Even though the physical computer chips inside the controllers may be closely related, there are differences between the two controllers. Two of the most common examples of these systems are CNC machines and entire processes driven by PLCs.

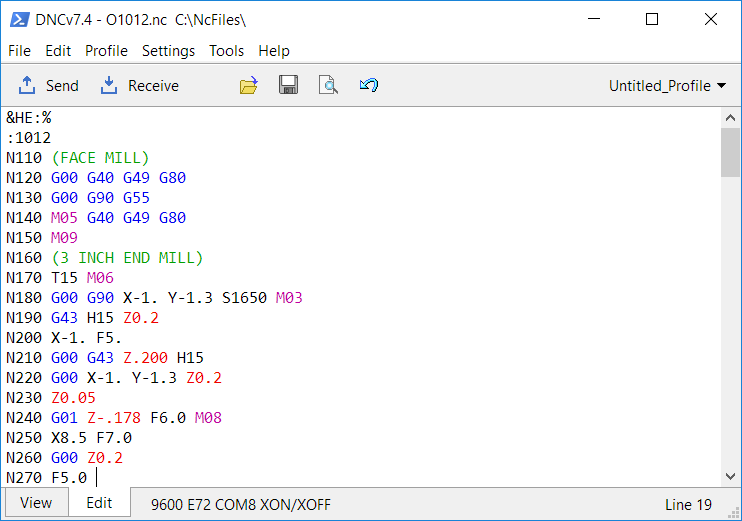

The only thing that old means is you will have a slow connection, your USB adapter or communication software won't care.Almost every modern industrial control system is driven by a digital processor. Typically you have three options on the wiring, lot's of fun! Add to that all the options in your communication software and you really start to go crazy. Also you have to make sure your control is set correctly for how you have your cable wired. Getting your computer to communicate with your cnc control involves getting the standard settings correct, including for the cable you are using, such as how many wires you have hooked up. They are only $5-$10 for a single port card.

CNC COMMUNICATION SOFTWARE SERIAL

Even though motherboards no longer have serial ports they still have a header to plug one into. Best option, for a desktop, is a serial port card.

CNC COMMUNICATION SOFTWARE DOWNLOAD

Just make sure you download the right driver. I have a FTDI USB adapter and it works fine. AGG's program is much more involved and does't like something about my cabling to one of my mills, it loads real slow to the control. I also find it much easier to set up with a new machine.

CNC COMMUNICATION SOFTWARE FREE

HyperTerminal is just so much easier to use for simple file transferes than any other free program I have tried. I have both HyperTerminal and AGG,s free dnc software installed and working on my computer.

0 kommentar(er)

0 kommentar(er)